Projects

- Categories:: Design Software Assembly Machinery Manufacturing Service

Development, building and implementation of a adhesive automation system with dosing management system

- Categories:: Design Software Assembly Machinery Manufacturing

This assembly unit combines high precision, cycle time and product variety in one. We achieve the resulting quality through the sophisticated combination of image processing and robotic assembly.

- Categories:: Design Software Assembly Machinery Manufacturing Service

This fully automated robot cell guarantees high quantities with consistent quality and combines multiple process steps such as gluing, joining, UV hardening and testing in one unit.

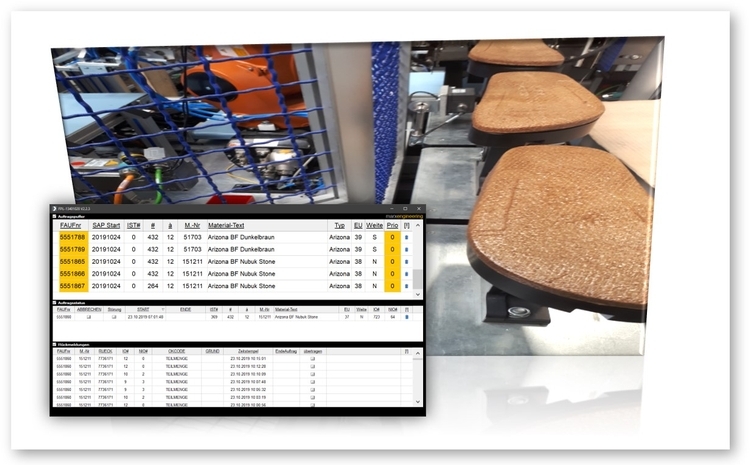

- Categories:: Software Engineering

A MES might be seen as an intermediate step between, on the one hand, an enterprise resource planning (ERP) system, and a supervisory control and data acquisition (SCADA) or process control system on the other and is usually a special adapted application. Here we have programmed a solution between SAP® and a production line based on Siemens PLC.

Due to pollution of baking plates during wafer production, a periodic cleaning is necessary to guarantee the final quality of the outcoming product. Our customer is developing a new system to clean baking plates fully automatically with laser technology. We help to supervise the process with the use of image processing.

Due to pollution of baking plates during wafer production, a periodic cleaning is necessary to guarantee the final quality of the outcoming product. Our customer is developing a new system to clean baking plates fully automatically with laser technology. We help to supervise the process with the use of image processing.

- Categories:: Software Engineering

VPD and OVPD (Organic - Vapor Phase Deposition) are technologies to produce organic electronics like OLEDs by deposit of special semiconductor materials. The Organic Electronic Cluster (OEC) is based on this technologies and offers a wide range of process modules needed in the field. We have taken over the vacuum concept and supported the customer by programming and commissioning of a demo cluster in the course of a temporary employment agency.

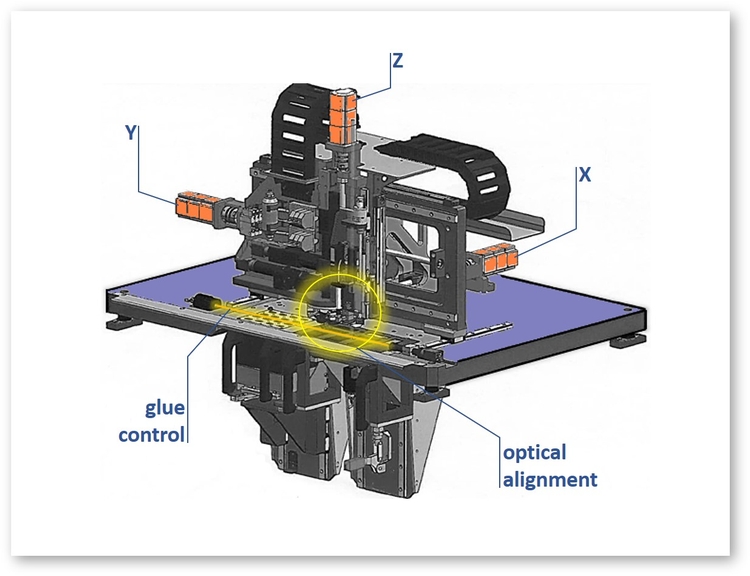

- Categories:: Design Software Assembly Engineering

The microlens array used here is an array with an area of 2.8 mm² and 280 lenses. We designed the electrical hardware architecture, programed the software , and made the electrical installation to position and bond the microlens array with a multi-axis control unit and optical image processing in 6 degrees of freedom up to 100 nm.

The microlens array used here is an array with an area of 2.8 mm² and 280 lenses. We designed the electrical hardware architecture, programed the software , and made the electrical installation to position and bond the microlens array with a multi-axis control unit and optical image processing in 6 degrees of freedom up to 100 nm.

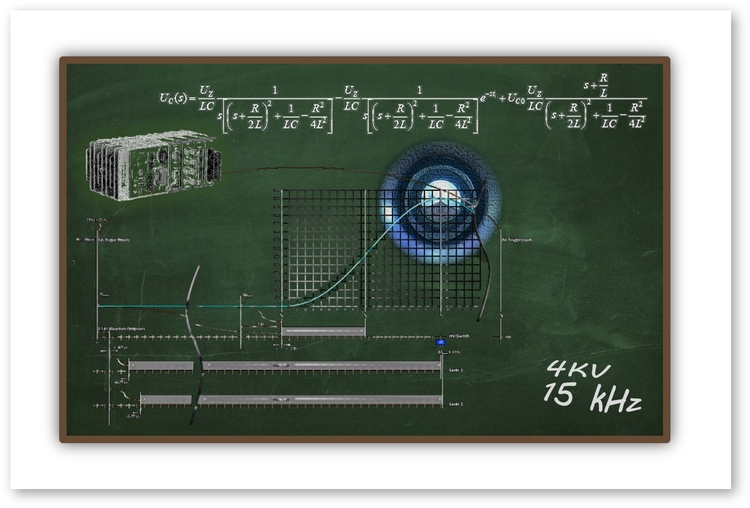

- Categories:: Design Software Engineering

Up to 15000 times per second a defined high voltage must be generated between two electrodes by resonant charging and discharged by trigger lasers. We have developed such a system from scratch and achieved unprecedented accuracy.

Up to 15000 times per second a defined high voltage must be generated between two electrodes by resonant charging and discharged by trigger lasers. We have developed such a system from scratch and achieved unprecedented accuracy.

- Categories:: Design Software Assembly Machinery Manufacturing

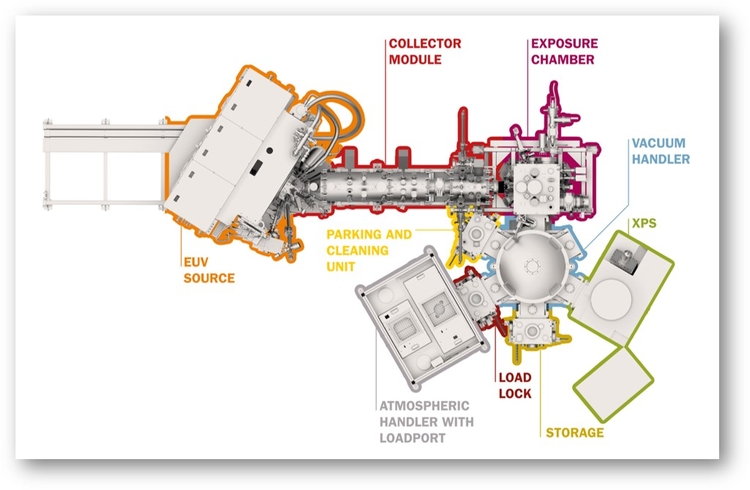

To operate an EUV-LDP-Source, media and processes must be regulated and controlled in real time. In order to evaluate the hardware and software used for this purpose, a simulator is not only helpful but also saves enormous costs since the real machine is not occupied. For our customer we have developed such a simulator.

- Categories:: Design Software Assembly Machinery Manufacturing Engineering

The Tin Handling Box (THB) is a core module in a Tin based LDP-SOURCE (see for this also the other projects about EUV-LDP-SOURCES). Before such a complex module is used for the first time or after a refurbishment, it must be tested in all operating phases from heating-up over operation to cooling down again. We have completely designed such a testbench and have already delivered it several times.

The Tin Handling Box (THB) is a core module in a Tin based LDP-SOURCE (see for this also the other projects about EUV-LDP-SOURCES). Before such a complex module is used for the first time or after a refurbishment, it must be tested in all operating phases from heating-up over operation to cooling down again. We have completely designed such a testbench and have already delivered it several times.

- Categories:: Design Software Assembly Engineering Service

To operate an EUV LDP Source, a tin plasma must be generated and controlled in a high vacuum environment using high voltage. Together with our customer we have developed, built and programmed the entire environment of such an EUV source.

To operate an EUV LDP Source, a tin plasma must be generated and controlled in a high vacuum environment using high voltage. Together with our customer we have developed, built and programmed the entire environment of such an EUV source.